Spun Pile Vs Rc Pile

Suitable for installation in a variety of soil conditions. High buckling resistance and no cracking due to 70.

Advantages Of Pre Stress Spun Piles Vs Rc Square Piles

Spun pile is a prestressed concrete pile.

. 50 years of maintenance free performance without special surface treatment. Lower cost than steel and cast-in-situ piles. What is Square pile.

Cheaper and easier transportation due to lower weight of pile. PHC PILES ADVANTAGES. Best choice for the environment.

50 years of maintenance free performance without special surface treatment. What is RC spun pile. PCK1 Ref Code Item Description Unit Rate MarkSuppLast Up CodeUpdated Trade HeadingA - Piling Continued Prestressed Spun Concrete Pile A087 600mm diameter x 15m length class B8 m 51051 17072011 A088 600mm diameter x 12m length class B8 m 52271 17072011 A089 600mm diameter x 9m length class B8 m 56139 17072011 A090.

Compressive strength around 70 mpa where rc square ones are only 30 -designers favorite pile. Applicable Spun Pile Diameter 250mm to 600mm Applicable RC Square Pile Size 250mm to 400mm Self Weight Excluding c ounterweight 178t to 200t Overall dimension Length x Width x Height 111 x 100 x 91 1355 x 120 x 744 Minimum clearance required for piling works Centre jacking 55m to 69m Bearing pressure on sleeper Up to 175kNm2. PC Square piles is the oldest pile type used in the world.

Spun pile is produced by a centrifugal with arange between 20g and 30g to improve the concrete strength comparing to square piles. Less permeability which works to protect the pile from air and chloride and not to cause the rust. Advantages of Pre-stress Spun Piles vs RC Square Piles Report this post Hamidreza Jamali BSc MBA.

PHC PILES ADVANTAGES. Best choice for the environment. High buckling resistance and no cracking due to 70.

Easier quality control after piling for being hollow. Hume RC Piles carry the SIRIM Certification under Quality System MS ISO 90012008. 5 6 inch wall Typical Design Loads 250 to 800 tons Pile Properties High strength concrete fc 7 ksi f pe 12 ksi 16 ft long pile segments typical Segments combined and post-tensioned.

It is a massive pile and therefore its cross sectional area is always the same for. Precast concrete piles are reinforced concrete piles which comes in different shapes. Suitable for installation in a variety of soil conditions.

Spun pile is one of the types of piles are widely used in the world construction for example in building and bridge. They could be circular rectangular square or octagonal shape. Spun Piles vs RC Square PilesSpun Piles haveBetter Bending ResistanceHigher Axial CapacityBetter Manufacturing QualityAble to Sustain Higher Driving StressesHigher Tensile CapacityEasier to Check Integrity of PileSimilar cost.

The allowable capacities for the concrete piles on design build basis is from 125 to over 750 kips per pile. This type of concrete is suitable for using in special condition such as river marine or high chloride soil. High buckling resistance and no cracking due to 70.

Higher bending moment due to pre-tensioning designers favorite pile. Lower weight prevents damage in transport and installation. To suit different soil and design conditions Hume RC Piles are available in two classes for each and every pile size ie.

Best choice for the environment. PHC PILES ADVANTAGES. Suitable for installation in a variety of soil conditions.

There are two types of precast concrete piles which are as follows. Spun Pile is the concrete products by using the advantage of prestressed concrete to concrete strength such as a bearing capacity required by the designer. Wide Selection Of Pile Sizes and Classes.

Spun Cast Concrete Cylinder Piles Typical Sizes 36 42 48 54 66 inch OD. Lower weight prevents damage in transport and installation. Jianhua construction materials group is the biggest spun piles manufacturer on the world.

Lower cost than steel and cast-in-situ piles. Lower cost than steel and cast-in-situ piles. Price List Name.

Lower weight prevents damage in transport and installation. Higher tensile strength due to pre-tensioning. Hume RC Piles are manufactured in sizes ranging from 150mm x 150mm to 400mm x 400mm.

50 years of maintenance free performance without special surface treatment.

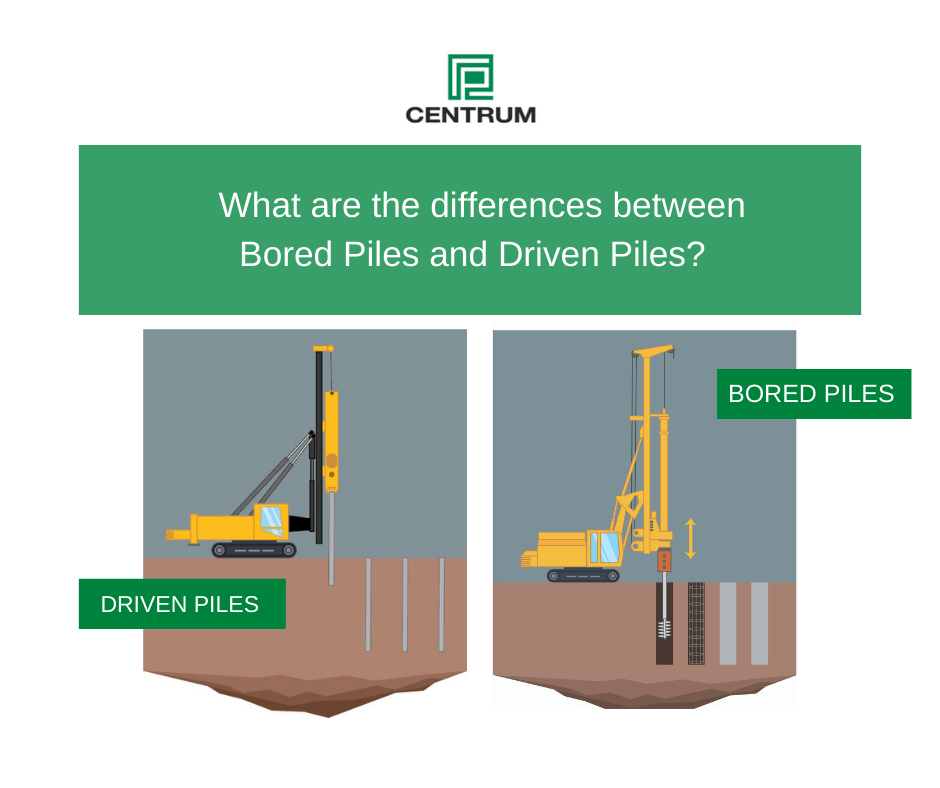

Types Of Pile Foundations Based On Construction Method

Different Types Of Pile Foundation And Their Use In Construction

Pile Foundations Types Of Piles Cassions Understand Building Construction

Detail Of Rc Spun Pile Specifications

What Are The Differences Between Bored Piles And Driven Piles Centrum Pile Ltd

Detail Of Rc Spun Pile Specifications

0 Response to "Spun Pile Vs Rc Pile"

Post a Comment